Bosch Rexroth, the drive and control division of Bosch Vietnam, is introducing its solutions and technologies in drive and control for the packaging industry at PROPAK VIETNAM 2016 - the leading international trade show for food, drink, and pharmaceutical industries in Vietnam.

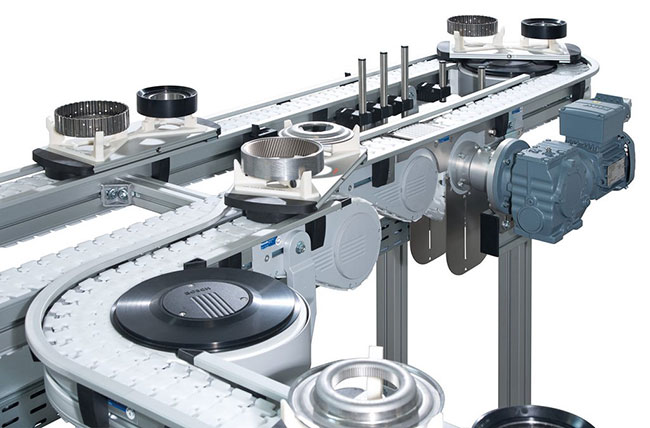

Its flagship product - VarioFlow plus chain conveyor system, which offers advancement in simplicity, flexibility, ease of assembly and configuration, enables packaging lines to deal with ever smaller batches, more frequent product changes, and a large number of product variants. With its low-noise operation, the system also helps reduce noise and improves working conditions in manufacturing areas. Furthermore, this chain conveyor system helps manufacturers achieve a fast time-to market and increase productivity.

Participants can visit Bosch Rexroth at booth H10 to experience the cutting-edge technologies and solutions for packaging, and get technical consultation from a team of local and international experts.

Moreover, visitors can also watch a demonstration of Bosch Rexroth’s modular Mechatronics Training System mMS4.0, illustrating the steps of Industry 4.0 production. The modular Mechatronics Training System mMS 4.0 focuses on a cube assembly divided into three stations which describes a complete factory and is highly applicable for technical and vocational training at universities and educational institutions. At this event, Bosch Rexroth introduces the station with robot system transferring products to storehouse.

PROPAK Vietnam 2016 takes place at Saigon Exhibition and Convention Centre (SECC), Nguyen Van Linh, District 7, Ho Chi Minh City, from March 1 to March 3. The exhibition is expected to attract thousands of local and international visitors.

Bosch Rexroth bundles global application experience in the market segments of mobile applications, machinery applications and engineering, factory automation, and renewable energies to develop innovative components as well as tailored system solutions and services. Bosch Rexroth offers its customers hydraulics, electric drives and controls, gear technology, and linear motion and assembly technology all from one source.

Bosch started the first operation in Vietnam in 1994. The headquarters of Bosch Vietnam is located in Ho Chi Minh City and is legally registered in Dong Nai province. Bosch Vietnam also has two other branch offices in Hanoi and Danang. Since 2008, Bosch Vietnam has started to invest into the gasoline systems plant in Long Thanh Industrial Zone in Dong Nai. This is the first high-tech production plant for continuously variable transmissions (CVT) pushbelts in ASEAN. The total investment for the plant will be €260 million ($282 million) by 2016.

In 2011 Bosch inaugurated the Software and Engineering R&D Center, the Robert Bosch Engineering and Business Solutions Vietnam Co., Ltd., and since then has employed more than 900 engineers. After that Bosch established the Automotive R&D center in Ho Chi Minh City in 2014. Bosch Vietnam is active in 6 different business divisions, namely automotive aftermarket, drive and control technology, packaging technology, power tools, security systems and thermotechnology.

In 2013, Bosch also established a technical industrial apprenticeship (TGA) training center in Dong Nai. The dual education program is developed based on German vocational training standards with an initial investment of $1 million to meet the increased need for local skilled labor.

By Hong Anh / vir